In our company yarn goes in and finished products come out.

We have always produced tights and stockings and, pair after pair, we imagine the moment when you will wear them.

Each product is created thanks to a series of closely linked processes, controlled and coordinated

with skill and experience. We believe that traceability is an added value, an important step towards

transparency. A quick way to let you know the soul of what you are wearing.

Oroblù Hub

The entire production cycle is carried out at the Oroblù Hub in Ceresara.

Discover our commitment

Oroblù is a brand born from the experience of CSP Internatinal Fashion Group. Home to brands of excellence in the manufacturing sector,

CSP focuses on transparency and traceability as the key to its eco-sustainable vision.

Commitment and Vision

We have chosen to invest in the future by focusing on a new vision of eco-sustainability, based on 3 pillars:

The preservation of resources, through attention to the use of raw materials.

Our aim is to become increasingly independent from renewable raw materials, preferring recycled pre or post consumer or bio-based yarns.

We are committed to developing production processes with reduced environmental impact.

We have introduced a partial recovery phase for dyeing water, which reduces water and electricity consumption. From 2020, we have chosen to use only electricity from renewable sources.

Transparency and traceability through the 'Made in CSP' project.

We intend to tell people where and how the tights and stockings we produce are made. Over the years we have built up an important treasure trove of experience, which we cherish at our factories in the province of Mantua (Ceresara), preferring Italian production wherever possible.

We love our Territory

The CSP Group was founded in 1973 in Ceresara (MN) thanks to the entrepreneurial skills of the Bertoni family, in the geographical area of Europe's most important industrial hosiery district.

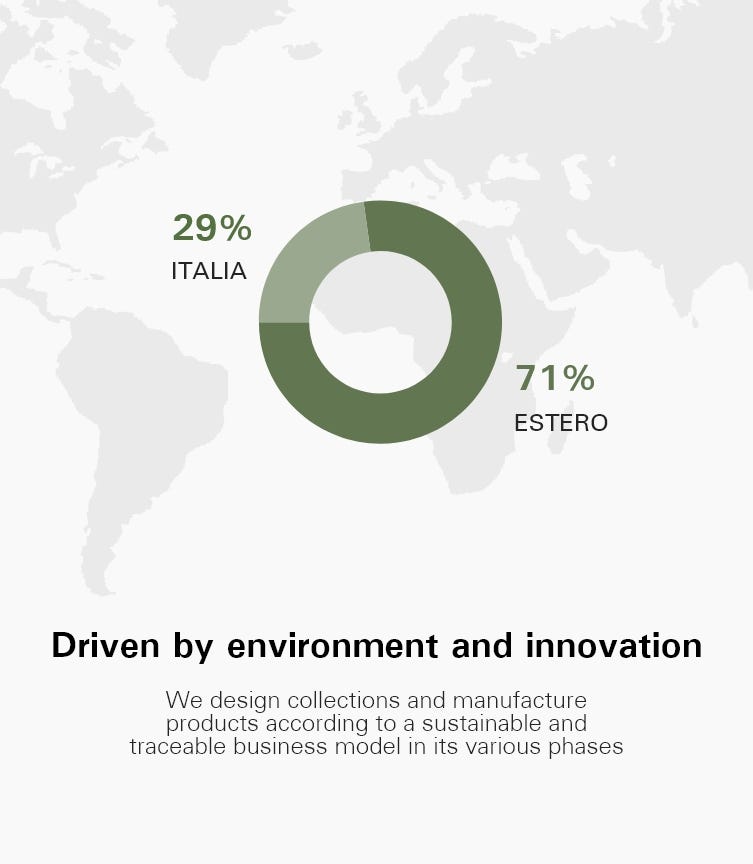

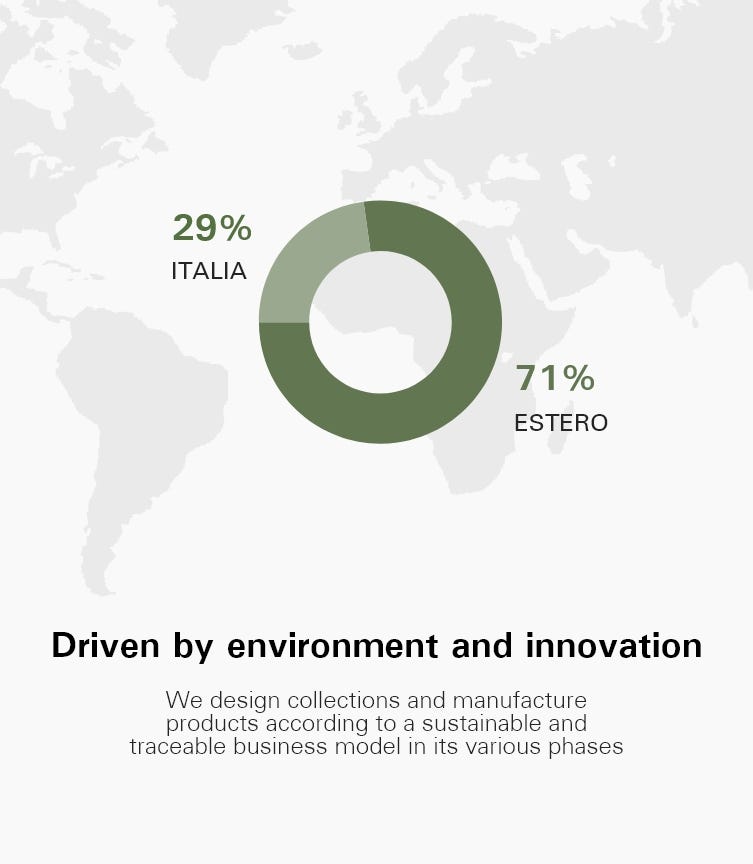

Today we are an international reality that produces and distributes hosiery, underwear, swimwear and innovative clothing all over the world.

We look beyond...

Today we are an international company producing and distributing innovative hosiery, underwear, swimwear and clothing worldwide.

- 91 mil €

DISTRIBUTED ECONOMIC VALUE - 661 Employees

OF WHICH 63% WOMEN - 24,5%

SUPPLIES FROM THE TERRITORY - -49% vs 2019

REDUCTION IN EMISSIONS

Our Principles

- Transparency and reliability

We are committed to providing transparent, truthful, complete and accurate information. - Fairness and good faith

We always work with commitment, diligence and professionalism. - Confidentiality

We consider confidentiality to be a fundamental rule and we scrupulously observe respect for privacy. - Compliance with laws and regulations and observance of rules of conduct

We observe the law of the countries in which we operate and the corporate rules we have set ourselves. - Equality and impartiality

We avoid any discrimination in the treatment of employees, collaborators and customers. - Value of the individual and human resources

We recognise the centrality of human resources as an important factor in the success of any business.

A story of sustainability

2020

- Products developed according to the logic of reuse, recycling and sustainable packaging.

- Selection and use of recycled and recyclable raw materials.

- Selection and management of suppliers with a short chain approach to guarantee quality and limit transport needs.

- Attention to the environment through the use of electricity from renewable sources, the reduction of packaging, the recovery of dyeing water and the use of environmentally friendly raw materials.

- Organisation of skills transfer through mentoring for an HR programme that looks at internal promotion.

- Governance aimed at internal training and constant promotion in the areas of eco-sustainable commitment, respect for data protection (RGPD) and application of occupational health and safety policy.

- Commitment to the local area in the strong contribution to employment and support of local events.

Our 2030 horizon

A global challenge: 17 goals to transform the world

Adopted in 2015 by the United Nations, the Sustainable Development Goals (SDGs) represent a far-reaching programme of action that aims to guide institutions, businesses and communities towards a more sustainable world.

Austria

Austria  Belgium

Belgium  Bulgaria

Bulgaria  Croatia

Croatia  Cyprus

Cyprus  Czechia

Czechia  Denmark

Denmark  Estonia

Estonia  Finland

Finland  France

France  Germany

Germany  Greece

Greece  Hungary

Hungary  Ireland

Ireland  Italy

Italy  Latvia

Latvia  Lithuania

Lithuania  Luxembourg

Luxembourg  Malta

Malta  Netherlands

Netherlands  Poland

Poland  Portugal

Portugal  Romania

Romania  San Marino

San Marino  Slovakia

Slovakia  Slovenia

Slovenia  Spain

Spain  Sweden

Sweden  United Kingdom

United Kingdom  Vatican City

Vatican City  United States

United States